Introduction

To the point

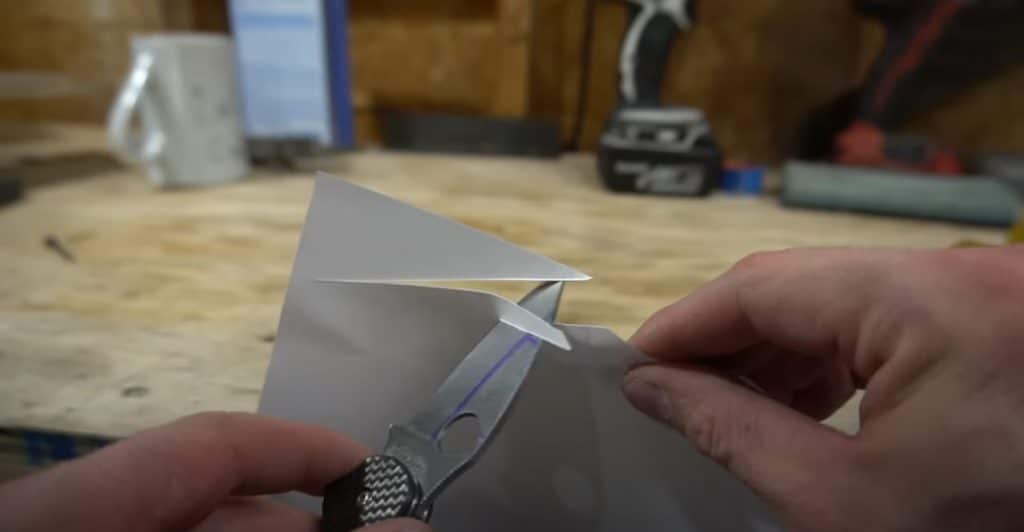

When choosing a knife, which can be folding or fixed blade, hunting or fishing, urban EDC or tactical, camping or survival ceramic or plastic knife, you should pay attention to the type of steel.

Along with the geometry and design, the material of the blade is the most significant element that determines how the knife will work. Blade material is an alloy of carbon and iron that includes elements to enhance characteristics.

Manufacturers create different steels by changing the number of added elements in the alloy. They also actively produce steel by rolling, forging, sintering, and heat treatment.

To make your tool perform the proper functions, always pay attention to good steel when buying a knife. It is a significant rule that you should consider if you do not want to waste money.

Read on and find out about what all professional homesteaders, survivalist fans, and budget preppers should know!.

The main properties of knife tool steel

Knife steels have many properties that everyone needs to take into account when choosing a knife. Today, the most popular type of knife steel is stainless A2 steel. A2 steel received its wide distribution due to its positive characteristics. Thus, tool steel A2 is non-toxic and resistant to corrosion. Fasteners made of A2 steel are practically non-magnetic, strong, and durable. They perfectly retain their properties at high and low temperatures.

Knife blades are made for cutting, it’s obvious. The goal of people who choose a knife is to find what they need, what they expect from the steel, and its parameters. The strength/impact toughness is a vital feature for a tool used in harsh environments, such as non-folding knives. Better corrosion resistance is significant when you use your knife in high humidity conditions.

In general, when it comes to working with a knife, the following factors that determine steel quality become the most primary:

- Stain resistance

- Good wear resistance

- High hardness

- Good toughness

- Good chemical composition

- High tensile strength

- High chromium content

Thus, many characteristics need to be taken into account when choosing knives. When making knives, manufacturers take into account seven main factors that affect the quality of the tool. Let’s look at them below.

1) The Sharpness of edge retention

It is how long your knife blade holds edge retention. No one likes a dull knife. When opening boxes, gouging wood, meeting stupid rope-cutting standards, you expect your knife to hold its sharpness for as long as possible. This quality of steel is readily apparent when you compare knives with premium and some budget steel. For instance, woodworking cutting tools always have an excellent edge because they perform cutting functions. Even a slight distortion of the knife-edge affects its quality. That’s why it is vital to choose a tool with low distortion and full hardness.

2) Strength/impact toughness

3) Corrosion resistance

Is where you’re using your knife wet? Saltwater? Cooking using citrus or tomatoes, for example? Some tool steels are so tough that they easily endure all these tests, resisting such unfriendly conditions with an ease that other steels can only envy. On the other hand, tool steels with high carbon content do not have the best rust resistance and need to be maintained to avoid corrosion. Therefore, it is always better to wipe them dry and lubricate them with some mineral oil after use.

4) Ease of sharpening

It is a very subjective but significant factor. As a rule, you may sharpen some knives easily and without much effort. However, a cutting tool with not good steel does not lend itself to quick sharpening. In survival conditions, the ability to quickly fix/sharpen a knife is, if not a matter of life and death, but quite vital and resource-consuming. On the other hand, a knife with steel that is quick and easy to sharpen will not show good retention of sharpness.

The determining factor that gives the steel its particular properties is its composition. Chemical elements contained in the alloy directly determine whether it will be hard, what environmental conditions it will be able to endure, what internal structure it will have, and much more? Also, an important aspect is the percentage of a particular element.

5) Heat treatment

The exact tempering temperature defines the amount of hardness removed. High hardness after a TMO increases sharpness retention by adding brittleness. Low hardness increases strength/impact toughness, decreasing the time retention of sharpness of the cutting edge. The effectiveness of high-temperature treatment, of course, is highly dependent on the composition of the steel.

6) Blade geometry

Indeed, cutting properties improve if the knife is cut very thin. Roughly speaking, the thinner the edge retention, the better the knife cuts. Undoubtedly, the overall thickness of the blade and the size/shape of the flanks also matter.

7) Wear-resistance

A2 steel is one of the best steel that provides good toughness due to wear resistance. If you buy a knife made of such steel, you will not regret buying it! High wear resistance is the property that makes your knife the best of the best. The uniqueness of the tool with high wear resistance and strength lies in its durability.

A2 steel: Chemical Composition

Many knives today are made of A2 tool steel. It belongs to the family of high wear resistance steels with a very high content of two important alloying elements at once – chromium carbide and molybdenum.

It is excellent air-hardening tool steel known for its strength and retention of cutting-edge properties. Its air-hardening tool steel means that it does not allow for additional hardening/thinning. Its outstanding strength makes it the most commonly used material for combat knives. In addition, blades and points made of this steel are appreciated by people of those professions who often perform woodworking or quality hunting. A2 steel knives are popular among hikers and hunters.

As for the composition of such steel itself, it contains a lot of chromium carbides. Thanks to this content, A2 tool steel has toughness. Here are the key elements of the steel composition:

- Carbon and chromium

- Nickel and molybdenum

- Vanadium and manganese

- Silicon and copper

- Phosphorous and sulfur

By the way, the Rockwell hardness of A2 steel is from 57-62 HRC. The content of more chromium carbides, manganese, and molybdenum provide such hardness. For this reason, stainless steels for a knife with strength and durability are the best option!

A2 steel foreign equivalents

In addition to the Japanese model, there is also an excellent variant of the GB Cr5Mo1V made in China. Like A2 steel, this low volume model has high strength and durability.

As for the use of A2 steel, people use it in the manufacture of many tools. Here is the main list:

- Blanking tools

- Punch dies

- Trim dies

- Forming dies

- Gauges

- Shear blades

- Stamping dies

- Dowel pins

- Die trimming

- Bark river knives

- Chuck Jaws

Final Words

To sum up, when choosing a high-quality knife, it is vital to consider the properties of its steel. Excellent knife steel provides high performance and contributes to the durability of the tool.

So, A2 steel is an excellent option for making a knife and other survival tools. Its main advantages are high strength, ease of sharpening, and low price. Besides, this steel does not need an additional heat treatable process (tempering) for stress-relieving. The strength indicators of steel are preserved during the operation of products at temperatures up to +425 degrees, even if you heat slowly. Perhaps the key disadvantage of A2 steel is its low corrosion resistance.

If you are looking for a high-quality knife for hiking, survival, and hunting, the A2 steel tool is what you need!

Frequently Asked Questions (FAQ)

Does A2 steel rust?

Overall, this steel has excellent characteristics. It belongs to the group of austenitic and therefore has high strength, wear-resistance and is amenable to all types of mechanical processing. Even though the steel is stainless, it nevertheless has low corrosion resistance.

Is A2 steel expensive?

As for the price category, A2 steel belongs to inexpensive steel. Hitting the average price point, A2 steel offers the optimal price-quality ratio. This makes this type of steel one of the most common both customers’ and manufacturers’ choices.

What’s the difference between A2 and D2 steel?

D2 is a “semi-rusting” alloy tool steel made in the USA. Die steel has good dimensional stability and is often used for high-speed cutters and industrial knives. This type of steel is used in cutting tools performing with high intensity and temperature without losing its maximum hardness qualities. That’s why it’s sometimes referred to as high-speed steel. Although it’s not 100 percent resistant to deterioration, it has far better corrosion resistance than A2 tool steel. A small difference lies in the chemical composition, although the toughness of these models (carbon steel A2 and D2 steel) is equivalent.

Does A2 steel make a good knife?

A2 tool steel has found widespread use in knife blade production. With the appropriate hardening and machining of the blade, the A2 steel offers an optimal combination of cutting-edge retention, wear resistance, and easy sharpening. As a result, it is an optimal variant for combat and hunting knives.