Almost every one of us has faced a situation in 2023 when your car failed you, and you need to use an off-road jack. Each time it happens, you need to think about how to use your off-road jack properly. It becomes especially hard if you use different types of jacks.

And if you also find yourself among the people who struggle with the usage of various types of off-road jacks, this article is for you. Here we will give you the list of the most popular jacks as well as some advice on the correct applications of different types of this necessary instrument.

The most popular jacks

So, let us start our journey to the world of off-road jacks from the description of the most popular off-road jacks and their advantages and disadvantages.

Hi-lift jack

Hi-lift jack is probably the most popular type of jack on the market, and you can find a hi-lift jack at almost any jeep or truck in the country.

The general information about hi-lift jacks is the next:

- About 50 inches long

- weight about 30 pounds

- weight capacity up to 3.5 tons

The main advantage of hi-lift jacks is the fact that they are great at working with large wheels, which is extremely beneficial if you have a truck. Also, they are slim and would not take a lot of space at the back of your truck. Moreover, such jacks are very easy to use, yet still, they have pretty decent lifting power.

However, there are also some disadvantages. Firstly, such jacks usually have many internal components, which might cause some unpleasant noises. Moreover, if you need a decent base, you have to buy it separately.

Hydraulic bottle jacks

The next most popular type of jacks is the hydraulic fluid bottle jacks. The main information about hydraulic jacks is the next:

- about 8 inches tall

- lift range about 4 tons

- weight about 8 pounds

- rugged base

Such jacks have many advantages; firstly, if you have a car with low clearance, a hydraulic jack would be the best choice. Also, these jacks have very low maintenance.

The disadvantages of a bottle jack are that it usually has a low base and has a limited lift range. Also, with time they might start to leak.

Aluminum floor jack

Floor jacks are another popular type of off-road jack that is also used for lifting various vehicles. And the main points about these jacks are the following:

- Wheels for easier transportation

- Steel corpus

- 2.5 feet tall

- decent lifting range

- sometime two-piece handle

- weight about 60 lbs

An aluminum floor jack has one main advantage, which is the reliability of this instrument. Also, they are pretty secure and allow you to safely lift your off-road vehicle. The main disadvantage that an aluminum floor jack might have is the size; not every off-road auto might fit an aluminum floor jack.

Other jacks

Here we would briefly mention some other types of jacks; we would not spend a lot of time on them because they are either less effective in lifting or they are not so widespread:

- Trail jacks

- Farm jacks

- Handyman jacks

In general, these jacks have pretty similar construction and can lift about the same weight.

Pulling of a car

Now, when we have discussed various types of jacks, we can speak about how you can use your jack from the most regular to the other uses which might even seem to be somehow strange ways of rescuing off-roaders from the danger.

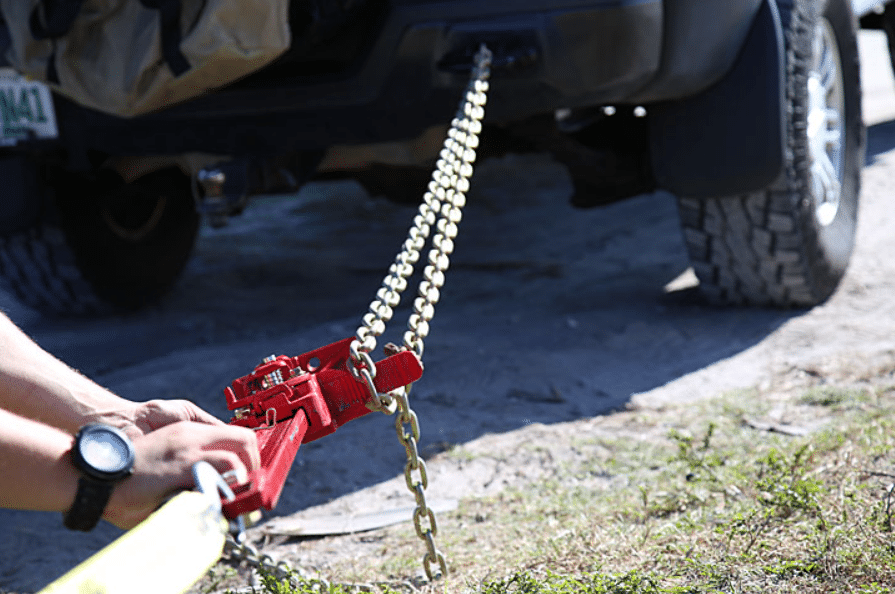

The first and the most conventional use of this instrument is pulling of a car that for some reason needs to be moved, for example, if it gets stuck in a trench. To get this job done you have to use a hi-lift jack. This instrument can help you to move your car by 10 centimeters per one rep.

The process itself is very easy. You have to find a chain and some kind of a clog. When you get those materials you can start moving the car. Firstly you need to attach the jack arm to the anchor point (make sure that the point is reliable). When the jack is attached you can wrap one end of your chain around the foot and the other end you ought to attach to your auto.

Finally, after you have done everything that we have described above you can simply use the jack in a regular manner.

The whole operation seems to be simple, however, there are some moments to which you have to pay additional attention. For example, one of the most frequent situations, when a jack is needed to pull a vehicle, is when it gets stuck in very deep and tough mud.

Often, such cases end with a vehicle being seriously damaged because of the wrong usage of the instruments and because of the wrong technique which can cause wrong angles that are dangerous for undercarriages.

If you find yourself in the same situation our advice would be to firstly free the wheels of the vehicle from mud, and for this task, you need a shovel. Secondly, you would have to lift your auto to place it at a normal angle.

When your vehicle is relatively free from mud and is in a more or less adequate position you can start to use the jack. Attach cable or chain in a manner that we described in a previous part of the article, but in this case, you have to place an anchor point as straight as possible. Also, do not try to use the whole tension of the chain or cable, the tension should be strong enough to support the jack itself.

Gradually, with the movement of the jack, the angle under which it is placed would become dangerous, so you would need to reset it. Here you have to remember that before moving the jack you firstly need to realize the tension because moving the lifting jack while the chain or cable is under tension can be extremely dangerous. If you can not realize the tension you can just way until jack falls on the ground naturally.

Tire placement

Another frequent case when you need a hi-lift jack is when your tire needs to be replaced. It can often happen when you are driving off-road through some harsh terrain, for example in marshes.

Such terrain is very dangerous and in many cases, you can not just winch your auto either with the conventional usage of an off-road jack or sometimes even with help of other cars. The solution can be using the hi-lift jack in a rather unusual manner.

You need to lift the front of the vehicle with the hi-lift jack to the point when the wheel would be above the water or above the trench line. Then you can push the vehicle off the hi-lift jack and it will move the auto for about 20 inches.

Afterward, you can make the same operation with the rear wheels of the vehicle. Here you have to be very careful in placing your hi-lift jack, because wrong placement may result in severe damage to the car especially if your jeep does not have some convenient lifting points.

When the vehicle is high enough you can push it again so the wheels of the jeep would be beyond the trail where it got stuck. When it is done you can change the gear and easily drive your jeep out of the place.

When using a hi-lift jack in such a manner you have to be extremely cautious because the lifting of a jeep can be very dangerous, especially for the hands, so it is probably better to use gloves. The process is indeed dangerous and the hi-lift jack is not the safest instrument, but if you are diligent enough you can get it done without injuries.

Off-road jack in an emergency

It might seem to be strange but indeed, you can use an off-road jack in case of some serious emergency on the road. We hope that such a situation would never happen to you, however, it is always better to be prepared.

So, the main use of jacks in the case of road emergencies is to spread something. In road accidents frequently people get stuck in cars or trucks and there are basically no ways to free them with your bare hands. But a jack can work as an emergency spreader. Basically, you would use a jack for the extension of some parts of the vehicle in order to make a hole and rescue people through it.

Obviously, if you see a serious incident in an urban area it is better to wait for professionals from emergency services. However, if such a situation happens with some jeep somewhere in a forest you can use your jack and save someone’s life.

Axle Retainer failure

This part of our article is for the people who know how to distinguish SUVs from jeeps. Such drivers know that when you are trying to climb a hill you can hear your axle shaft giving up and breaking. In such a case you need to stop the jeep immediately.

When you stop your jeep, it is time to take the jack and the tools. To use a jack in this situation, you firstly need to disassemble it because you would need only the climbing rod. When you have the rod, you have to place it against the tire.

Such placement of a rod will allow you to move. Obviously, the speed would be like the speed of a turtle. Nevertheless, it would allow you to drive the jeep out of the dangerous zone.

Tire Bead

The next use of the jacks can help you to break a tire bead or to place the wheel on the ram. Again, such cases are not as frequent. However, if it happens, it is better to be prepared, especially when you and your jeep are somewhere in the country.

Obviously, in the case when you lose a wheel, it is better to use some safer options, but they are not always available. Therefore, you can use a jack to break the bead and reinstall the rubber on another rim.

Base plates and off-road jack

Above, we have already mentioned how you can use a hi-lift jack to free a jeep from the mud. However, here we will give you another way of liberating vehicles from the dirt. This technique is a bit odd and is mostly used when you are dealing with all kinds of soft mud.

The problems with the soft mud lie in the fact that you can carry a jack with very powerful movements, but the mud would not give up, and the jack itself would be covered in the mud pretty fast. Therefore, you would need the support of some kind of a baseplate to use with your jack.

A baseplate would virtually prevent the jack from burying itself in the ground. If you are lucky enough, your jack was sold with a lot of additional gear, including a factory-made plastic baseplate. However, it is not a problem if you do not have such a thing with your jack, because you can use a log or a rock for these purposes.

Also, you can use a spare tire; it would be especially convenient if you don’t have a farm jack. The process is easy, just put the wheel on the ground and stick the jack inside. If you have done everything right, the wheel will redistribute the force which goes from the jack to the ground; therefore, the jack would not be stuck into the mud.

This method can really help you somewhere in the backcountry. However, you have to be extremely careful, because either if you load the jack with too much force or because of the weakness of the wheel, it can break, and you would be left somewhere in nature without spare wheels.

In conclusion to the article, we might say that indeed off-road jacks are necessary if you like to drive off roads, because often only they can help you to lift vehicles that get stuck in harsh terrain. We hope that after reading this article, you know which jack you need to choose and how to use it.

Frequently Asked Questions — FAQ

What type of off-road jack will support my vehicle?

The exact unit that you would need for your auto depends on many factors. Obviously, some vehicles are bigger, and therefore they need more power, while for other vehicles, the weakest instruments would suffice. However, there are some additional conditions; for example, for cars with low clearance, you would need a bottle jack.

How much does an off-road jack weigh?

The weight of a jack depends on its type; for example, the bottle jack and trail jack have different weights. Also, it depends on whether your jack has some accessories; components also play a big role. But in general, most jacks have average weights.

Will off-road jacks fit in my trunk?

The answer to this question depends on the trunk of your auto. Also, it depends on the type of jack that you want to fit in, for example, a floor jack would require a much bigger trunk than other types.

Does my off-road jack require any maintenance?

In fact, any instrument in the world requires some maintenance, and jacks are not the exception to this rule. However, generally speaking, you do not need to spend a lot of time to maintain your jack in a decent state.